|

The technologies, studies, and components produced within the ASTRI program will be carried out to address the problematic for the CTA implementation. As it is today, the ASTRI allocated budget will cover:

- the realization of a small-size, dual-mirror telescope end-to-end prototype (SST-2M);

- the design of the mechanical structure and the prototyping of the critical components of a single-mirror small-size telescope (SST-1M);

- the design, development and manufacturing of part of the mirror facets for the SST-1M;

- the design, development and manufacturing of part of the mirror facets for a Medium Size Telescope developed within the CTA Preparatory Phase;

- the support to all the INAF CTA activities necessary for the finalization of the technological aspects, such as the completion of the scientific requirements, the Monte Carlo simulation, and the data handling.

Thanks to the INAF skills and to the high quality products by national Companies, ASTRI will mainly cover studies on the telescope mirrors based on the replica technique and the sensors and electronics for the camera.

The performance, reliability and responsiveness of the technologies developed within ASTRI with respect to the scientific and technical requirements of CTA will be proven through the construction of the end-to-end prototype.

In case of a positive feedback for the CTA community, it could be replicated into about 60 units that will compose the entire High Energy array.

This will lead to a major return for several Italian companies working on the related markets.

Mirrors

The Italian industry, thanks to INAF, is today a leading manufacturer of mirrors made with replication techniques for both space-based X-ray astronomy telescopes and Optical-UltraViolet ground-based telescopes.

The ASTRI funds will allow the development of the technologies best suited for the mass production of optical mirrors having moderate cost, high robustness and strong asphericity. The mirrors will be based on the techniques of:

- cold slumping, for mirrors with moderate curvature;

- hot slumping, for mirrors with pronounced curvature;

- Nickel electroforming replication from a pre-machined master-shape will be considered for special cases.

The technologies will be developed at the INAF-Osservatorio Astronomico di Brera with the involvement of industries as follow-up of a recent project dedicated to a manufacturing process optimized for large spherical mirror facets for IACT. The process is called cold-glass slumping.

It has been funded in 2006 within a PRIN-MIUR framework and adopted at the world’s largest Cherenkov telescope: the 17 m MAGIC II telescope.

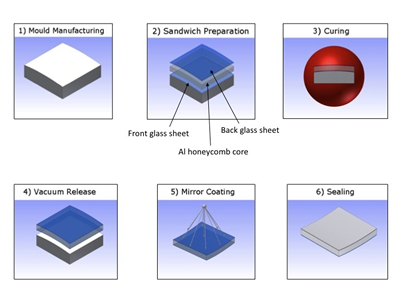

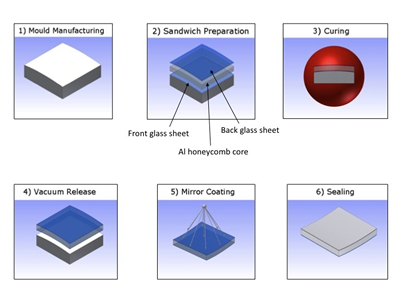

The chosen substrate has a sandwich-type mechanical structure that confers stiffness and low areal density.

A thin glass sheet is bent and is made to adhere to a mold having a highly precise shape. The complete panel is assembled by gluing a reinforcing core structure and a second thin glass sheet. After the glue is polymerized, the panel can be released and properly coated. The coating provides adequate reflectivity and protection against reflectivity losses and scratches.

Main manufacturing steps describing the cold slumping

glass technology developed in 2008 with a PRIN-MIUR grant.

One out of the 112 mirrors produced before being

installed on the MAGIC II telescope.

Sensors and electronics

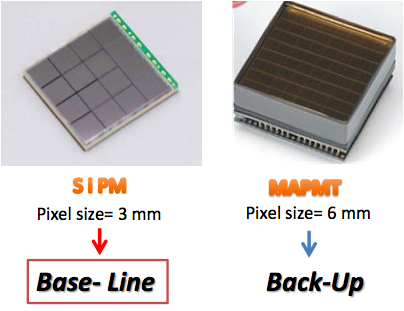

ASTRI will achieve another important goal: the use of fast and segmented Silicon sensors, a novel technology that will replace the present PhotoMultiplier Tubes (PMTs).

The advantage of adopting the Schwarzschild-Couder optical configuration consists in shrinking the focal surface maintaining the optical properties within the requirements of the project. Such small detection surface, in turn, requires a spatial segmentation of a few square millimeters.

The PMTs, while responding quite well to the scientific and technical requirements of Cherenkov telescopes, are worldwide manufactured under a quasi-monopoly and exhibit a high cost. This is particularly true for the case of the small pixelled Multi-Anode PMTs that are exclusively produced by the Japanese firm Hamamatsu.

On the other hand, among the commercially available light sensors that offer photon detection sensitivity in the 300-700 nm band, a fast temporal response and a suitable pixel size, the Silicon PhotoMultipliers (SiPM) represent an attractive alternative. Moreover, the use of these innovative, ultra-fast and segmented sensors could be compelling also for the medical sector.

An intensive work is in progress at the INAF-IASF-Palermo to model the camera in all its relevant aspects. A tridimensional mechanical model is under designing as well as an intensive characterization campaign is ongoing.

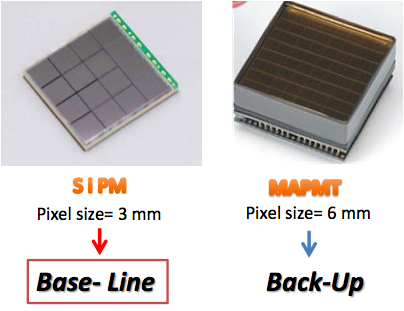

From left to right: Silicon Photondetectors (SiPMs) and

Multi-Anode Photomultipliers (MAPMTs) are the sensors that will be

studied. SiPMs are considered the baseline choice for the ASTRI focal

instrument.

|

Go to Foto-Gallery Go to Foto-Gallery

|

Go to Foto-Gallery

Go to Foto-Gallery